Literally…

Coming up this weekend is the Bladetech Lone Star IDPA Championship. As is usually the case, I have not been able to get in as many matches lately as I wish. I missed matches Wednesday, Thursday and Saturday last week. With the match coming up, I needed to be sure I had an adequate supply of suitable ammo loaded.

The last time I did much loading was in June. We had the wreck, which pretty much killed off July and much of August for recovery, but when I did get to shoot, I had ammo loaded already.

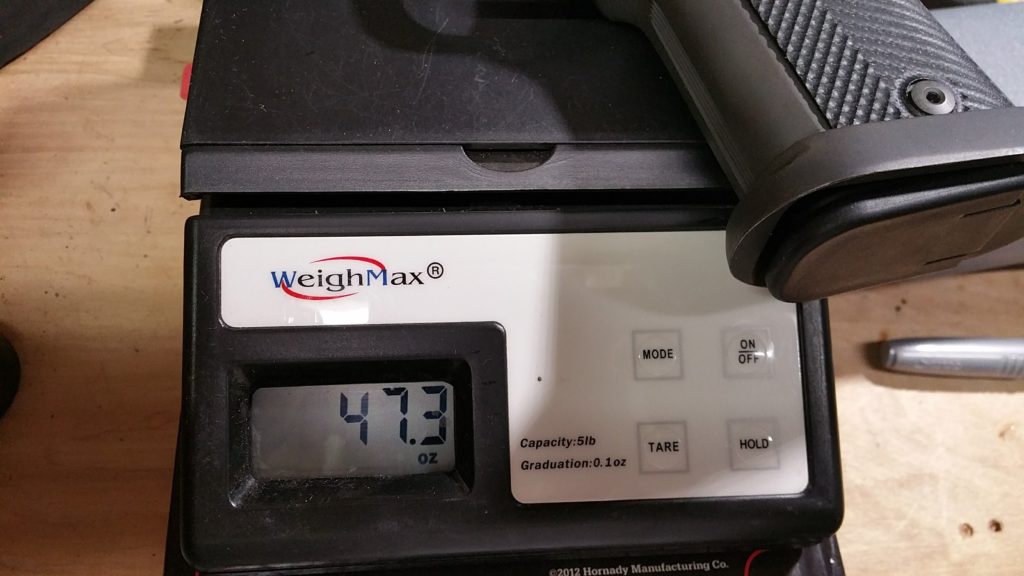

My favorite 40S&W load for IPDA is 180g plated lead bullets from Xtreme Bullets propelled by 3.9g of Winchester 231. It’s a nice soft recoil, very controllable. I was, however, concerned that it might not make required power factor.

I set up my chronograph right outside the workshop door and fired 5 round test groups.

The 3.9g load was pretty much exactly at 125 PF with average velocity of 697 fps. It takes 694 to make minimum, so that margin is just a little too close for comfort, unless I could guarantee identical performance on the chrono stage at Lone Star 🙂

So, I turned the powder measure up a little. 4.2g was a reasonable step up, raising the average velocity about 100 fps to 792. This makes 142 PF, which is noticeably hotter than the 3.9g load, but still very comfortable and controllable and plenty of margin for chrono slop.

Having ooched the load up by a comfortable margin, I started loading in earnest. Four and a half hours later, enough later for it to be dark outside, I reached a stopping point at 800 rounds total. My hands were tired, but I didn’t expect a blister. It developed overnight. Imagine if I didn’t have a roller handle.

This gives me enough ammo to have 300 for the match and 100 rounds per day for practice, assuming I can shoot somewhere each day. Of course, that first practice day will be with the 3.9g load, just to use it up.

Speaking of practice…

Last week, on one of the days I missed a match, I went to Shoot Smart and shot about 250 rounds. I used up all the 40S&W I had with me first, then just to play around some, I changed the slide and barrel out to 10mm. I wanted to shoot a magazine of normal semi-hot loads then a box of a much lighter 5.0g PowerPistol loads to compare the contrast. I shot a full magazine with 165 grain bullets propelled by (I think) 10g of BlueDot. That isn’t the hottest BlueDot load, but it’s no slouch, good for about 1100fps. I had changed magazines to the lighter load then before I shot again, I noticed something didn’t look right about the pistol.

Some months ago, I was swapping slides and barrels around. The combination that ended up in my gear bag was my spare Glock 20 slide, with the stock Glock 20C barrel.

The Glock C models have ported barrels in order to use some of the gas produced by the cartridge to help compensate for recoil. Thanks to Oil The Gun for this awesome still from their video of a Glock 23C shot in the dark.

All that gas vents upward in a V above the pistol, through matching ports in the slide.

Oops.

Note that I have the unported Glock 20 slide installed. That gas coming out of the ports on the barrel had to go somewhere and the dustcover offered the least resistance.

The worst of the damage is most visible above. On the left side, the plastic is seen having stretched enough to distort the area and on the right, enough to crack the plastic. Perhaps on a steel pistol, the damage would not have occurred at all, but at least the damage appears to be only cosmetic.

I put the pistol in a sort of cold traction, clamped in a soft jaw vice with a cord pulling the rest of the frame over. Left overnight, this corrected the bend about 50%.

I have verified with the match director for Lone Star that this should not be a problem with him or the safety officers. He recommended using a heat gun to do more correction, though.

My wife has an embossing heat tool, which is basically a heat gun with a pretty small nozzle, less than an inch. It makes a tightly controlled torrent of heat, which lends itself well to this task. Luckily, I am secure in my manhood because her’s is pink.

The frame is now even better, with the dust cover almost back in a line with the rails. It contracted a little more as it cooled and I was being very conservative with my adjustments. I also used the flat end of a drift punch to flatten the serial number plate from the inside, which will hopefully take away a little more of the tendency to spring back into the bent position. I will apply a little more heat for the final tweak.

Normally, I use the 20C slide, mostly because the stainless 40S&W conversion barrel looks pretty cool through the ports, even when the pistol is dirty.

That reminds me, must add Gun Scrubber to my shopping list…