It’s been a long enough project started long enough ago that I may be a little soft on some fine details, but I’ll try to get it all.

Since I took a fair number of pictures while working on this antenna, the EXIF info helps me nail down some dates.

After much discussion with friends, most notably KD, I decided on a Hustler 6BTV, a 6 band trap vertical. I ordered it from Texas Towers on May 22, 2012. It was $265, including shipping. They offered the best price by a small amount, but I had to wait for the antenna to come in from the manufacturer. I don’t remember when it finally arrived, but on June 4, I sent an email asking about it and it was still not there.

Due to that delay, I ended up ordering the remaining accessories from DX Engineering and upon reflection, I probably should have ordered it all from them for convenience sake. At the very least, they rewrote much of the installation manual, accounting for some real world issues.

I decided that my barn/workshop would make the best permanent hamshack facility, mostly so I would not have to fill a room in the house with equipment and endure the scorn of my beloved. 🙂 So, I decided on a flat spot equidistant from the workshop and a pasture fence.

I drove a galvanized pipe, really a chain link fence rail, into the ground to mount the antenna to.

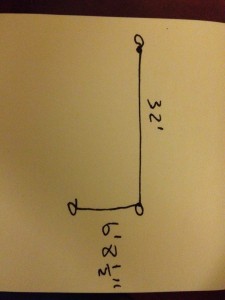

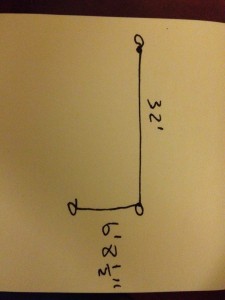

I decided on using 30 radials of 32 feet each. This was a reasonable compromise between the number of radials and keeping the cost down. These dimensions would use almost all of two 500 ft rolls of 12ga THHN wire, about $100. I did a little math and found that the chord of a 12 degree arc of 32 foot radius is close enough to 6′ 8-1/2″ and made a string jig for laying out the radials.

Using the jig and marking paint, I laid out for all the radials.

Since the grass in this area is not exactly putting green density, I presumed I could not depend on staples and growing grass to secure the radials, so I elected to use an edger to dig narrow trenches to bury them

The ground was very dry, it being the middle of June. This made cutting the trenches easy, but burying the radials difficult. The method that end up working best was literally hammering the edges of the trench to collapse it over the wire. My arms are still tired years later. I suggest watering the area the night before next time.

Making the radials was a pretty intense assembly line. It doesn’t seem like 30 would be that much, but it took two solid evenings to roll out 32 foot lengths and put ring connectors on one end of them.

I got the radial plate from DX Engineering and enough stainless steel hardware for 30 radials. *My* plate didn’t come with the hardware like it does now…

With Field Day 2012 now coming up the following weekend and the trench technique limiting me to only getting 6 of them in the ground, I simply laid the rest of the radials out directly on the surface, with nails at the ends to keep them straight.

On Field Day, we had Amy, Jesse and their daughter out for operations. They brought a TS-140 and a dipole so we could run 2 rigs. We had limited success with the dipole; we didn’t really have a way to get it up in the air and it was too close to the ground to perform well.

In fact, RFI was pretty horrendous in certain bands. We had a fan to help keep us somewhat comfortable out there. It has a wireless remote control and RFI from the dipole toggled the fan on and off, sometimes per spoken syllable. It was kinda funny, but darned unhandy.

In any case, we had fun and made a few contacts (Cat 2E, 109 QSOs, 488 points) even though the antenna had not been properly tuned. The TS-450SAT’s built in tuner kept SWR at a minimum.

After Field Day, the loose radials were rolled up then later removed, but the antenna was not disturbed for almost a full year. Though I had done some preparation, I was unable to participate in 2013 Field Day due to a schedule conflict. Anytime I can spend the day welding and working metal with my stepdaughter, I’m there.

In January 2014, I left the house one morning and rounded the corner to find our horses wandering the streets. I knew immediately that I would not be able to corral them without lead ropes, so I rushed back to the barn and grabbed some. I was distracted and in such a rush leaving the barn that I hit the antenna with the truck. I mean, I mowed it down. WHAM!

The thin galvanized pole, which had held up more than a year of winds on the plains could not withstand the RAM. That night, I looked over the antenna and found that, while it was damaged, it was not really as bad as it looked.

I would really only need to replace the bent lower section and the 10m trap.

Somewhere between January and June, I procured replacement parts directly from Hustler, which turns out to be manufactured in nearby Mineral Wells, and rebuilt the antenna. As seems to be the pattern, with Field Day 2014 fast approaching, I resumed antenna work.

I used a new heavy galvanized pipe. If I hit it with the truck again, it will resist more, which, come to think of it, may or may not be a good idea 🙂

I re-marked the ground for the radials, cut new trenches and got several more buried, assisted by a redneck tool I made to help push the wires into the trenches from a standing position.

I also had purchased DX Engineering’s tilt mount because taking the antenna down to tune and adjust it was going to be quite an undertaking. Also, the tilt mount provides an opportunity to easily secure the antenna in inclement weather.

One may note that, at this point, the antenna system as built (and rebuilt) had become pretty much all the same components that DX Engineering offers in a package. The main difference is that this package comes with only enough wire and hardware for 20 radials 25 feet long and it’s arguably less costly at $514, if for no other reason than combined shipping.

Field Day 2014 went wrong early because I strained my back during setup on Saturday morning and spent the day hurting and barely able to walk. Luckily, most of the day was also spent sitting. We were storing a large camper trailer for a friend of ours and we were encouraged to use it if we liked. In order to be in air conditioned comfort for the day, I set up the station in the camper. It made for as pleasant of an operation as would have been possible.

2014 Field Day results: Cat 1E, 111 QSOs, 472 points

Again after Field Day, the remaining above ground radials were rolled up and essentially no antenna construction action was taken until Field Day preparations began in 2015. There were related developments, though.

The radials are not impervious to accidents. I snagged a buried radial with one of the forks of the hay buggy.

Although the workshop is a neat place to hang out, there are advantages to being able to operate from elsewhere, so I got interested in RemoteRig.

Many rigs these days have removable and remotable control heads. RemoteRig is basically a hardware device that extends that remote cable over a LAN or WAN. Particularly well suited to this method is the Icom IC-706 and variants. Even if your rig doesn’t have a removable head, but can be operated remotely via CI-V or other such data formats, RemoteRig helps remote that data and, perhaps more importantly, the audio, over a network. For the curious, it basically uses SIP protocols and is thus pretty much just a slightly specialized VoIP phone. Sadly, it is not an inexpensive solution and it took me a long while to pull the trigger on the $530 purchase, but I have been very pleased with it.

The extension cable for the IC-706 is now out of production, but you can find them on occasion. I actually got mine from an eBay seller before I considered RemoteRig simply because I might one day put the rig in a vehicle. It is quite an emotional undertaking to cut a rare cord that people are asking $150 or more for these days. When I got mine, they were still in stock at Universal Radio for $60.

The workbench is somewhat in disarray, but here is my Icom with RemoteRig extending the control head over the LAN switch in the workshop.

Once that was working, it was trivial to move the control head into the house to test it from there.

It takes a little firewall holepunching to set up the system to work over a WAN, but here it is sitting on my desk at work

So, in the above pic, pressing the band button on the control head sends a serial command over the cable to the RemoteRig unit, which encapsulates it in a SIP message that it sends out the ethernet port over the LAN at the office to the router, through our provider to their firewall, onto the wild internet to my provider, down the DSL wire to the house, through the DSL modem and it’s built in switch, over the long range wireless link from the house to the workshop, to the switch in the workshop, to the RemoteRig device where it is turned back into a serial command that is passed over the cable to the radio. The radio responds and replies over the same chain. There is a generally imperceptible delay to the user pressing the band button.

Almost as an aside, I decided that to support remote operation, I need to add an automatic antenna tuner. The LDG IT-100 is operationally very similar to the Icom AH4 tuner, connecting directly to the radio and triggered by the front panel button on the radio. It can tune as for as 10:1 SWR on HF, but most importantly, it can work for those small mismatches on either side of my antenna’s resonances.

Though operating remotely over WAN is neat, at this point I really intend for it to be used most often so that I can operate from in the house on occasion. I ended up using it for Field Day 2015.

I started working on the antenna a little earlier this year, late March instead of mid June. I got a few more radials in the ground.

Pleased with the success of operating in the camper for 2014, I decided to do about the same for 2015. The friend’s camper was long gone, but we have our own vintage camper, a 1972 Jayco Jay Wren. It’s a cute little thing.

As part of the preparation for the upcoming event, a week or so before FD 2105, I moved the camper from it’s usually parking place to just outside the workshop. I opened the door and was immediately concerned because there were hundred of dead bees inside.

A little more digging revealed that there was a fairly well established hive in one of the storage benches.

I (inadvisedly) sprayed a number of them, but there were too many and really I don’t like doing that, particularly to such a beneficial creature. I was able to locate a beekeeper who came out and was able to capture and relocate the hive. It was quite an involved process and, long story short, the camper was not going to be usable for Field Day.

So, I probably could have set up in the kitchen using RemoteRig, but instead I used my wife’s craftroom. This would keep me out of the way and free of most of the distractions in the house.

The laptop was used primarily for logging, though I did try to make a few digital contacts. Note the RigBlaster interface behind the control head. The network latency does not appear to be an issue for digital modes, either. Note also the rubber ducky antenna on the back of the RemoteRig device. Using WiFi makes it all that much easier to use at home. The RemoteRig with the wifi adapter needs only 12V power to be ready to use anywhere in the house.

Due to extreme knuckleheadedness, I did not submit the logs for this Field Day. Unofficially, I had 57 QSOs, operating as a 1D station.

Believe it or not, there are STILL a few remaining radial wires that have not been buried. My neighbor and fellow ham had rented a trencher for a project at their house, so I borrowed it and cut three trenches I needed as well, one for power to an outbuilding, one for water to the barn and a shallow one for the coax to the antenna. My LM400 coax is rated for direct burial and buried coax can help choke stray RF currents, even though I do have a set of 1:1 baluns for that.

As it stands today, there are just a few radials, maybe 5 or 6, left to bury plus one to repair from the coax trench digging. Once those radials are in the ground, the only task left is to finally tune it as built.