After a rocky start from sniffles and sneezes and other such symptoms on Friday, we hit the road for Oklahoma, namely the Turner Falls area.

It’s very nice up there, nice riding, yada yada…

Sunday morning, I noticed a bit of oil on the ground under the yellow trike. This oil was in a rather irregular patch, as opposed to a nice round spot. I found some fresh oily wetness near the oil cooler hoses, so I presumed that was where the problem was. It wasn’t a whole lot of oil and the dipstick reported plenty of oil, so I decided we’d just keep an eye on it for now.

We took off down the meandering path to home. Twenty some-odd miles into the trek, we had cause to stop. It was a little chillier than expected when we left, but not quite so chilly once we were underway, so Gabby needed to shed a layer of clothing. Whilst we were stopped, I checked the leak.

Ummm, there was a LOT of oil all over the engine and exhaust and everything back there.

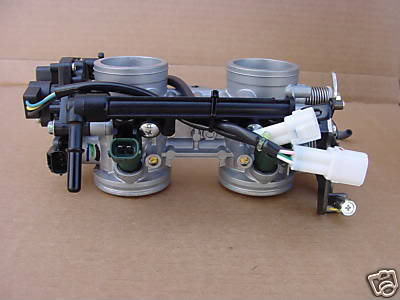

With a little testing and looking and revving the engine, etc, I determined that the lower tubing on the oil cooler was leaking. I first thought it was leaking from the hose, but then I saw that the cooler tubing itself was bent and leaking from a crack in the tubing.

It was a simple enough matter to remove the cooler and bypass it with one of the hoses. The weather was mild and these engines tend to run cooler in trikes than cars anyway. I didn’t even get very dirty doing it.

Fast forward a bit to our late lunch in Ardmore. I noticed as we were approaching Ardmore than there was as strange kind of “flex” feeling to the seat. I knew that it is mounted on 2″ X 1/4″ flat steel rails and thus had some springiness to it, but this sensation was different and had developed recently just during the ride. When we stopped at a restaurant, I discovered that the “body” of the trike, the blocky structure covering the engine and surrounding the rear seat, would bounce independent of the suspension. I started bouncing it gently and observing where the flex was, fearing that some bump in the road had broken a weld or something equally nasty. I also observed that an existing crack in the left fender had worsened and during this bouncing, I could see why. Once I saw what the problem was, I got that sinking feeling, the one you get when you know what’s wrong and that it’s your own fault.

Remember back on October 7th, when I was working on replacing the throwout bearing, I said “Then there was the extraneous piece of metal that used to hold up something long gone by bolting it to the engine, but now served only to keep the engine and transaxle loosely connected to one another once all the bolts were removed”?

It turns out that a sloppy weld on a piece that *looks* like its supported elsewhere doesn’t necessarily mean the piece is unused. Turns out that it was an only slightly extraneous piece of metal supporting much of the weight of the body of the trike. Add to that a full gas tank, fill up the side boxes and strap on some luggage, and the now-known-to-be-cantilevered body puts too much stress on the 3/4″ square tubing frame that is welded here and there somewhat randomly.

Also now apparent was that the bottom of the oil cooler, having been mounted on said bouncy body, was damaged by slamming down on to the relatively immovable engine. Ah, I see said the truly blind man….

So, while munching and playing with Gabby’s new Nuvi, I formed a plan to brace the thing up so that the trip home would not result in any permanent damage. It took less than $8 worth of hardware from Lowes and the borrowing of cordless drill services from a Lowes employee who had been putting on some kind of cabinetry demonstration.

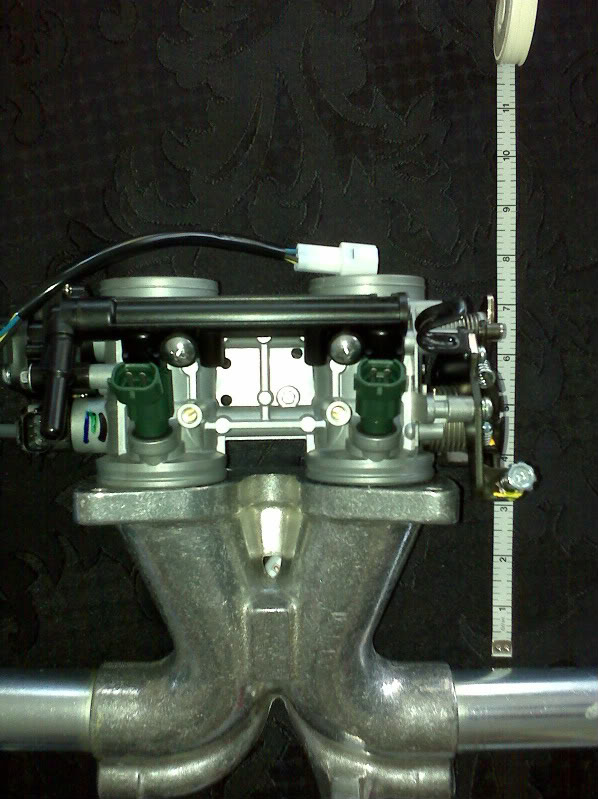

I took two 12″ long perforated angle pieces and braced between the top engine-transaxle bolts and the cross piece in the body. It’s probably more solid now than it’s ever been, and these are removable.

We got home without further incident, at least if you don’t count our headset batteries going dead and timing that took us by Texas Motor Speedway shortly after the races let out. We lost about an hour in that traffic.