I had a good long chop at the trike on Friday night and all day Saturday. As is usually the case, I got a lot done but less than I’d hoped.

I spent some quiet time Saturday morning finishing the connectors on the speedometer, switch pod and the cable connecting them to the rest of the trike. I am using small gauge wire and isolating switched circuits with relays so that I can have a small but most importantly multiconductor cable going to the handlebars. The switchpod has 10 or so wires and the speedometer has 12 or so. Because a few wires (power, ground indicators, etc) are shared between the two, I made the cross connections at the connectors on the frame side. This also lets me run a single wire for each function from front to back and all the wiring that goes on the body can jump to the body back there.

I also installed said speedometer and swtich pod….

This unit was chosen because not only does it display speed and mileage, but also engine RPM, fuel level (though I have not yet found and installed a fuel level sender; I will!), time and it has indicator lights for left and right turn, high beam, hazard, neutral and oil pressure.

I have something to connect to each of these indicator light. Turn, highbeam and oil will be as labeled. I will be substituting the alternator light for the hazard light, which I suppose indicates some sort of hazard. There is no neutral indication on the VW transaxle, but I think I will connect that light to the unused FIdle output in MegaSquirt and map it to indicate something useful, something like warmup or redline.

As a mildly interesting side note, all indicators except N and OIL light when power is applied. The N and OIL lights need ground to light. This works out in my favor on OIL because the oil pressure switch does indeed grounds when oil pressure is low and the FIdle output can be programmed for either, but by default, it grounds when active.

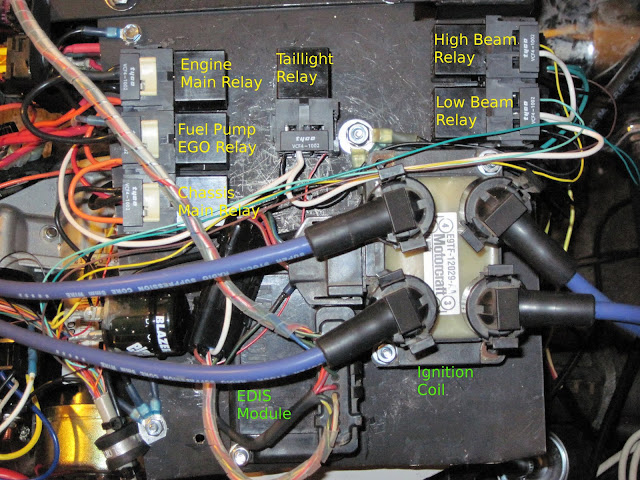

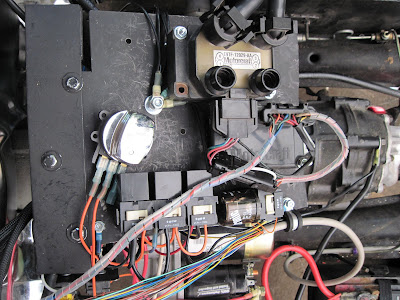

The two things that ended up delaying the most were rearranging the relay mounting locations to clear the slanted bit of the bodywork and wiring the fuse blocks.

I cut the panel shorter and am now rearranging relay sockets so that they clear the edges, clear each other and still have room for the relay to be replaced in the future. Way back when, the plan was that all the relays would fit in a nice straight line….

… but there just isn’t room to clear the back of the driver’s seat. There are now going to be relays all over the place. Oh, well. Reality bites.

Please note that the chrome ignition switch is only temporarily installed here.

I found, not surprisingly, that a two or three pin flasher will fit in one of my relay sockets. On one hand, it keeps a consistent look to all the wiring, but it also means I have added a socket when I really needed to lose one. 🙂

I also found, not surprisingly, that my turn signal relay is not enough load to operate the flasher properly. There are a couple of possible solutions. Arguably the best is to use a flasher made for LED lighting, which is not load sensitive and should flash a relay exactly as well as a light. They have been hard to find locally. I needed some more connector pins so I ordered them as well as a suitable flasher from DelCity.

The fuse panel wiring became needlessly complicated because of my own short sightedness. I originally wired all 8 fuses to switched power, forgetting that a few things, such as the actual ignition switch, need fused but continuous power, so I had to wire the fuse panel feeds a second time, four switched and four non-switched. Then I remembered that I wanted a separate power feed from a switched relay to so that a short in, for example, the brake light wiring wont blow a fuse that feeds the engine. To feed that relay, I needed a separate fuse, so I stole the top fuse on the panel, only then to realize that I had wired the top 4 as switched.

After all the connector moving and reterminating, I now have a main chassis fuse, 3 non-switched fuses and 4 switched fuses. Should be plenty.

The project is coming down to the wire. It will be tough to get everything left to do done in three available evenings this week so I can get an inspection on Friday and have it driving on the weekend. I can only try!