Boots arrived today. As expected, I will need to remake or possibly just rework my intake adapter plate.

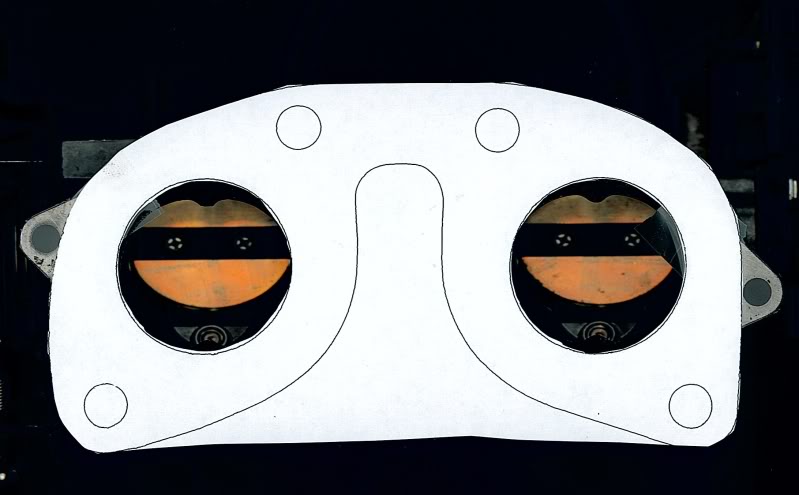

I trimmed the adapter plate I made a few days ago along the lines of the gasket to cleanly fit the manifold.

The boots, however, have mounting tangs that overhang an area that was cut away. My first thought is that I should cut a new plate, but I think I may end up time ahead by simply welding on the two “wings” needed for proper attachment.

I remembered from looking at a Versys at the IMS that the boots mounted such that the TB was presented to the engine at a slight angle, but its shallower than I remembered. I don’t think it will make much, if any difference. Because of the direction the throttle cable will need to route, the TB should end up tilted towards the doghouse.

From the techie showoff standpoint, that will be cool because the injectors and injector wiring and plumbing showing is cool. If, however, the throttle cable will have to bend too sharply between the TB and the doghouse, I’ll have to turn the assembly around. Well, the clean side will still be pretty cool.

I definitely want to salvage this adapter plate. I don’t think I could have matched the diameter and spacing of the holes any better! Still needs deburring, but the match up very nicely.

I think I will try to drill and tap holes for the boots and choose cap scres of the appropriate length to not protrude a lot on the gasket side of the adapter plate. They will just miss (or just nick) the gasket, so they will also probably just miss (or just nick) the casting on the manifold. Because the boot seals with an O-ring, I don’t imagine I will need 120 ft-lbs of torque to hold them down.

I want to run a brace between the adapter plate and a mounting tab at the top of the TB. This may end up being a bracket formed from some nice flat I have or maybe even just a long bolt.

On this TB, the stepper motor driven subthrottle shaft includes a cam that operates the throttle for fast idle.

MegaSquirt does not at this time support subthrottles, but it should be a simple matter to remove the subthrottle plates and use that motor for my idle air control.

Lastly, for this update anyway, I have yet to find any authoritative information on the flow rate for these injectors. I may try to work with it assuming that they are between 200 and 250 cc/min. If that doesn’t work out, I suppose I can rob a couple of the known 245 cc/min injectors off Buzz.