I had a few minutes Saturday morning and thought, hey, why don’t I go shoot 140-odd rounds of various ammunition through a couple of coat hangers glued to a clock?

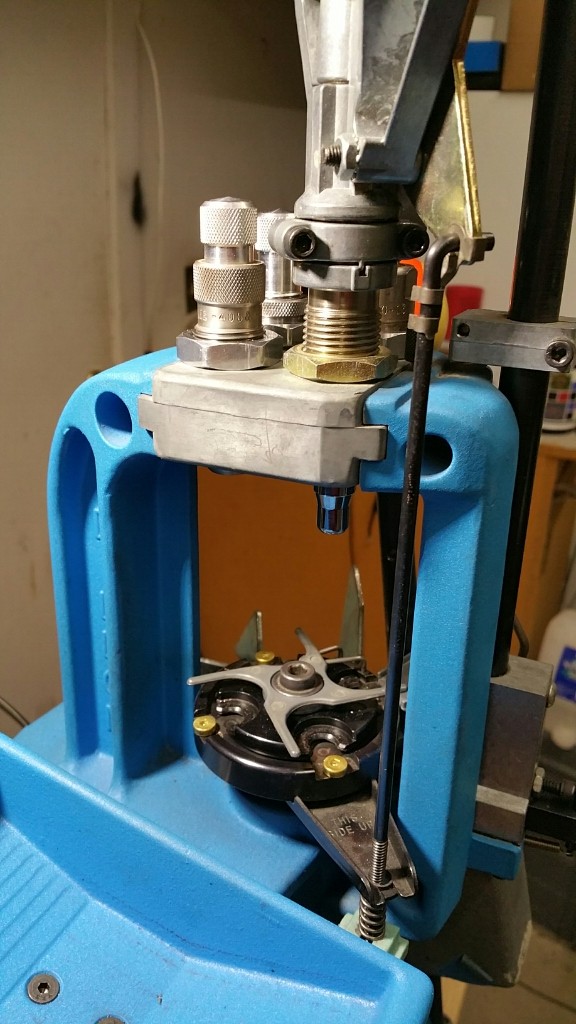

The object of the exercise was that, even though I’ve had the chronograph for a long time, I had not used for exactly what I had intended to use it for, evaluating the performance of my handloaded ammunition.

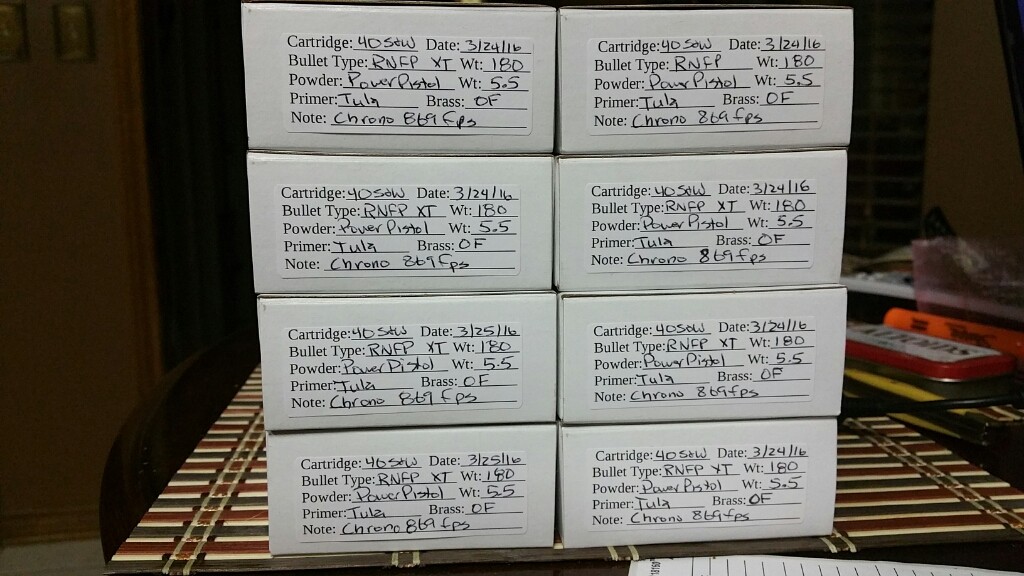

I gathered all the various handloads that I had on the shelf, (8) 40S&W, (5) 10mm Auto and (3) 45 Auto. I also grabbed a particular box of 22 to try out.

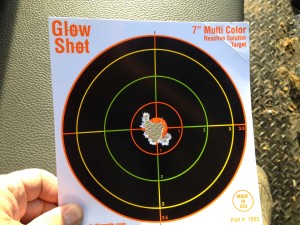

My handloads were almost all using Xtreme RNFP bullets at 155, 165 or 180 grain. The procedure was pretty straight forward. At the top of a spiral notebook page, I recorded the specifics of the load being tested, i.e. “40S&W RNFP Xtreme 180 / Power Pistol 4.40 / OF / CCI500” or some variation therein. I then list numbers 10 though 1 in reverse, Average, Spread and Standard Deviation. I then loaded the magazine with the load to test, took my position about 10 feet from the chronograph and fired a full magazine, pausing between shots to verify that the machine caught them. On rare occasions, it did not.

Once the magazine was exhausted and the pistol made safe, I would take the notebook to the chrono and review the string. The last shot is displayed then each press of the review button shows the next one back. I recorded each number, including the stats, marking the high and low velocity shots with a + or -, respectively. I then deleted the string from the chronograph and set up for the next test.

A “Err” display means that the first screen detected a projectile but the second screen did not. This is most often caused by aiming too high in the detection box, making it harder for the circuitry to catch the projectile. Honestly, I’m sometimes surprised that a chronograph works at all, let alone so well. For a 40S&W pistol round at 1000 fps, the chronograph has to notice a shadow that lasts about 40 microseconds across each detector. For the 7000 fps max velocity it is rated at, that shadow is about 6 microseconds. Light itself, which travels so fast that we only noticed in the last 300 years that it travels at all, can only go about 1 mile in 6 microseconds. In any case, I only had two Err displays in nearly 150 rounds, and statistics account for those missing shots.

I have several things to report about the results.

The oldest handloads I had for 40S&W and all the handloads for 10mm Auto were done before I discovered IDPA, so those are not particularly light loads. Most of my loads seeking a light recoil are much more recent.

A favorite load for that is 4.5g of TiteGroup, which I used interchangeably with 155 and 165 grain bullets. It is a very pleasing load to shoot. Recoil is slightly sharp, as in quick, but very light, not very forceful. It operates the pistol reliably. At a sanctioned match, they chrono’d at 960 fps. However, both weights with that load averaged 805 fps for me. I don’t know if ambient temperature can really make 160-ish fps difference or not. A quick Google reveals that on that match day, it was 83F and for my testing, it was low 50’s, 51F at 9:00AM.

Another interesting bit is that the the same powder charge with 155 and 165 grain bullets were essentially the same velocity, at least in this one narrow test, and assuming that the velocities were accurate, the power factor on both of these loads is essentially dead on minimum 125 for IDPA.

Similarly interesting is that a 7.0 grain charge of Power Pistol propels at 180 grain bullet faster than a 155, 10 out of 10 shots if the velocities are sorted.

Presented here in the order shot:

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

Avg |

| 155 |

1121 |

1064 |

1064 |

1059 |

1107 |

1083 |

1059 |

1028 |

1063 |

1113 |

1076 |

| 180 |

1121 |

1115 |

1096 |

1084 |

0 |

1111 |

1102 |

1131 |

1112 |

1101 |

1108 |

In this chart, the velocities have been sorted, lowest to highest. Ignoring the lowest since the test on these 180 grain bullets included one of the two Err displays, the 180 grain bullets are always faster than their 155 grain counterparts:

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

Avg |

| 155 |

1028 |

1059 |

1059 |

1063 |

1064 |

1064 |

1076 |

1083 |

1107 |

1113 |

1121 |

| 180 |

0 |

1084 |

1096 |

1101 |

1102 |

1108 |

1111 |

1112 |

1115 |

1121 |

1131 |

| variance |

-1028 |

25 |

37 |

38 |

38 |

44 |

35 |

29 |

8 |

8 |

10 |

As for 10mm Auto, I fired a magazine of a commonly available factory load, Remington UMC. The Remington ammo and all four of my handloads were numerically essentially indistinguishable from the Power Pistol 40S&W load, all hitting at or just under 1100 fps. The only one that stood out much was 7.5g of Unique, which had a noticeably sharper felt recoil.

I had only 3 available 45 Auto loads to test. With either a plated Xtreme bullet or a poly coated BBI, 5.6g of Unique produced a nice 180 PF load. The BBIs were noticeably smokier.

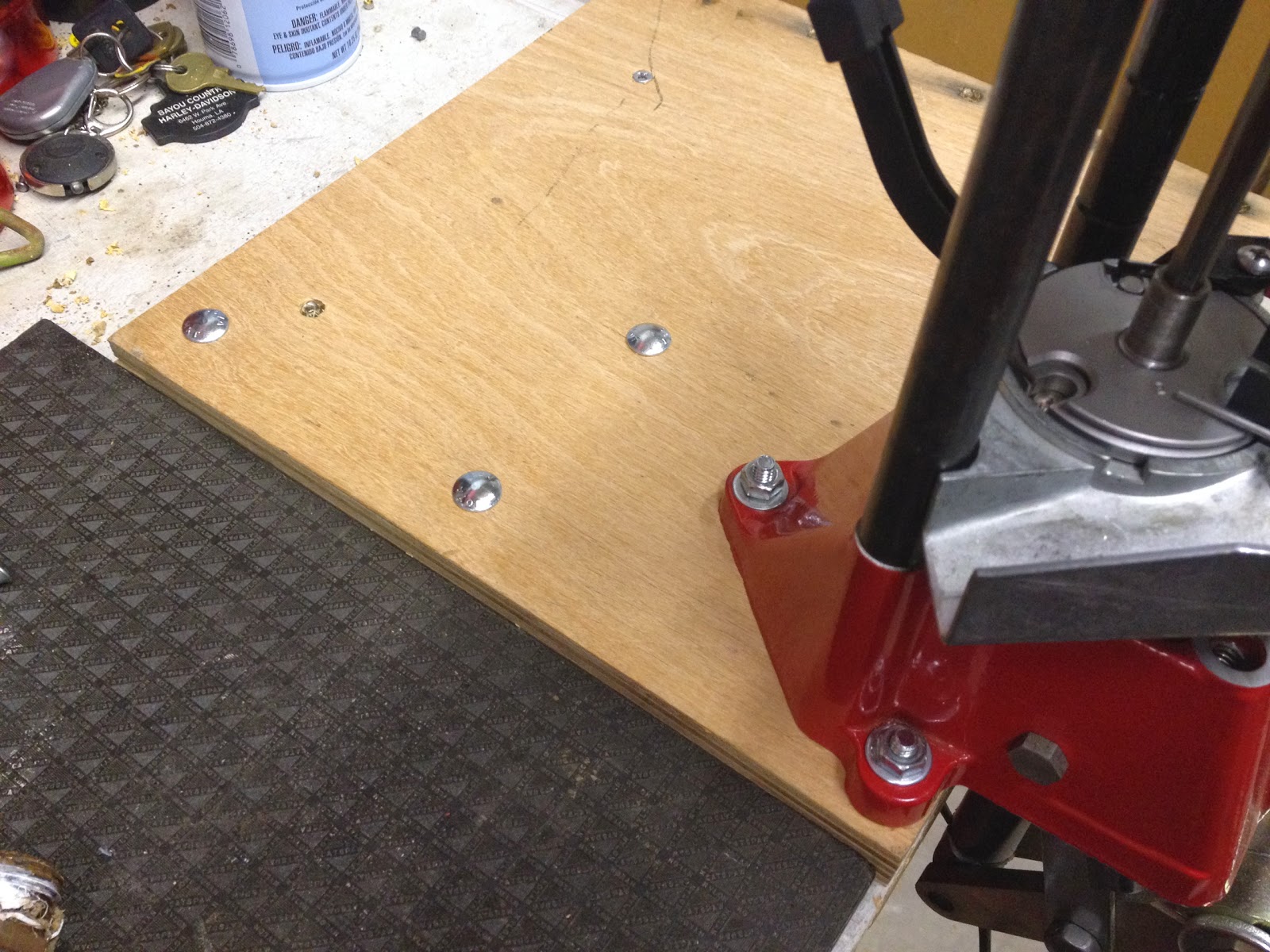

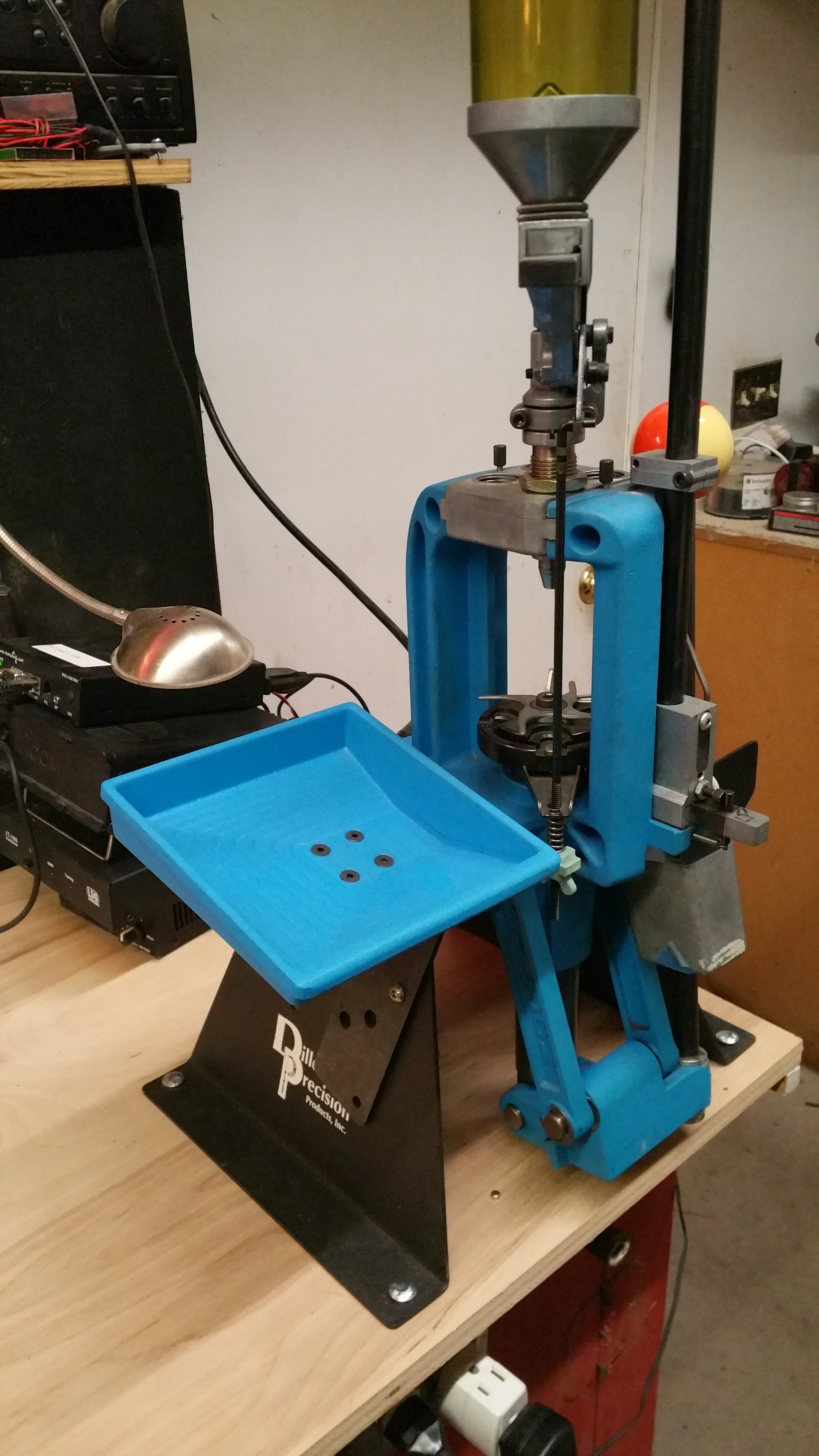

I did not remember until I began testing a lighter 45 Auto load of 5.2g Unique that I had experienced some problems with powder dropping in the old Lee press when I was just starting out with it. Much like my experience with them before, I managed to get off two good shots before a squib stopped testing on the 1911. I had not happened to bring a rod to clear said squib, so I just aborted testing the 45 Auto. The two shots were promising, averaging 685 fps for a power factor of 158. That is too low for legal CDP division, but there is room to tweak it up to 165.

Finally, I wanted to see what the Winchester Varmint LF load looked like. This is a hyper velocity 22 LR load that uses a bullet made of tin rather than lead. They come out of my 3.4″ Walther P22 barrel at a screamin’ 1200 fps, with a high mark of 1246. Imagine how they will do with a rifle barrel or even my Ruger or H&R revolvers.

It will have to be a manual action gun because not even one shot operated the auto pistol. Some stovepiped, but most didnt even extract that well. I will try it in the Ruger 10/22, but I am almost positive they will not work it either.

I have enough variety of 22 ammo that I want to do a 22 only test, testing all the various ammo in all the various guns. Stay tuned.