There have been a few developments since my last update. I guess I’ll cram them all in one post.

I acquired a small oscilloscope. The jury is still slightly out as to whether it’s appropriate to the application, but so far, so good…

There are some limitations to the instrument. The LCD display is not particularly high resolution, so sometimes it’s hard to see the whole story at once. Likewise, there no external trigger input, so the missing pulse nature of the trigger wheel signal is difficult to sync. One has to adjust the sweep rate low enough and manage to capture an entire revolution with the memory function to analyze the finer points and the LCD resolution limits how much you can see at that level.

Even so, I was able to see a few things. First, the slightest eccentricity in the trigger wheel mounting is very easy to detect and could indeed be a contributing factor to my EDIS ignition problems. The VR sensor input ranged from 5V p-p down to 0.5V p-p. It’s difficult with the resolution of the display to configure the scope to show both ranges. That alone could affect the EDIS module enough to cause some problems.

Working on a related theory, I set the sweep rate very slow and watched the average amplitude of the VR sensor signal. I arbitrarily decided that low RPM was “normal”. As the RPM went up, the amplitude went up to about 5V, then began tapering off, fairly quickly, to “normal” levels. Since the engine would not rev beyond about 5500 RPM, I am supposing that the stock VR sensor may not have the frequency response needed for this application.

Putting a little math to it, with the one pulse per rev stock trigger, the signal at redline would be about 9500 Hz, or 9.5KHz. With the 36-1 trigger wheel, the signal would be more like 332KHz to 342KHz, depending on how you count it. Keeping in mind that there are radio signals at lower frequencies than that, it’s not surprising that maybe the sensor is not up to the task.

It is under this working theory that I decided to, at least temporarily, return the ignition to Yamaha stock. This means I lose my cute purple wires and those “wrath of Thor” lightning bolt sparks, but it could return me to fighting a single front war.

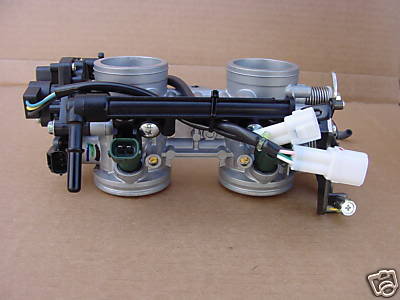

It turns out that it may be worth it, for now I can rev close enough to redline to cause the involuntary retraction of certain parts of my anatomy, and I’m not even riding at the time. There is some detectable miss in the rhythm, especially noticeable at low RPM. I may be suffering the famous Yamaha weak ignition problems, so I will still be searching for a long term solution, perhaps for Dyna coils or maybe driving the coils directly from MegaSquirt, maybe even with big enough drivers to run the EDIS coil. For now, however, perhaps I can march on with fueling issues and determine if I can even operate Buzz on these (quite likely too large) throttle bodies. Down that road are a few possibilities, from cutting my throttle body assembly in half and fabricating a manifold, up to and including restoring Buzz to stock and putting MegaSquirt on something else, probably the VW trike. My wife would like to see me get that thing on the road regardless.

I also shoehorned in an oil and filter change, which was probably overdue even when I parked Buzz last May.

Today, before I posted this update, I was explaining the issues to a friend when it suddenly occurred to me that the EDIS module itself may have a rev limiting “feature”. This could make sense because my module and coils came off a Tempo or Escort or some similarly pedestrian vehicle, RPM-wise. Web research, including in MSEFI forums, indicates that the jury is still out. Several people describe similar rev limitations, generally around 6000RPM, but some testing has shown 8000-9000 RPM as a limit.

I’m wondering if the VR sensor could *still* be the issue. Once one exceeds the sensor’s ratings, the module gets bad or no info about the crankshaft position and speed, so it stops firing. The engine RPM drops, the signal gets usable again and there it goes. Consequently, the Ford sensor may not work much better. Furthermore, the limit may indeed be a feature of the EDIS module itself, and that may explain why others *not* using Yamaha sensors on their EDIS modules are having similar problems.

One possible solution may be an optical sensor that may not would not be so frequency dependent. I will keep looking, but for now, I really want to get on with turning the fuel and maybe getting Buzz on the road, so it’s stock sparks for me.

All this, and I still haven’t properly investigated the throttle-failing-to-close-completely issue…