Last Saturday, I attended the Foundations in Shooting Sports class from Texas Defensive Firearms Training. I knew that I would get a lot of good information and coaching, but even expecting it, I was surprised how much of an immediate difference the instruction would make in my shooting skills.

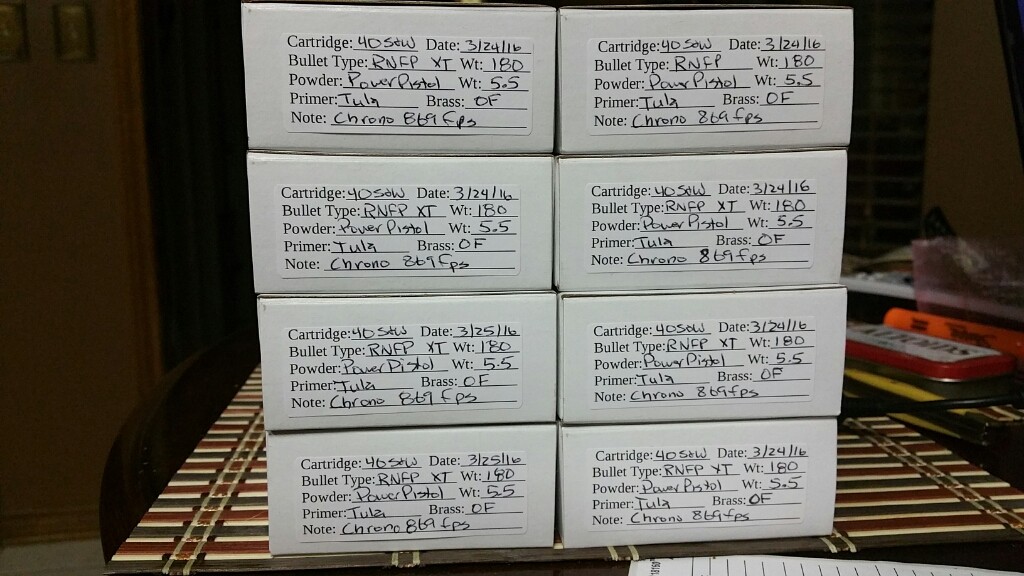

Before I continue, I’d like to report that my 5.5 grain Power Pistol loads functioned completely without incident, not counting one weak hand fail to eject that was likely from limp wristing the pistol. I have done that weak hand shooting before.

I am a fair marksman, particularly if given a little time, and I am always willing to learn more. I listen for pro-tips, whether directed to me or just given in my presence, I observe as best I can how the more advanced shooters I see at matches prepare and when someone gives me specific advice, I am quite likely to try it and to research it and maybe modify it. One such piece of advice that made a huge difference in my control of the pistol was when someone spent some time to help me establish the grip commonly called Thumbs Forward. I have big beefy hands that were allowing me to shoot OK, even with a poor grip, but a solid grip instantly improved my shooting.

I am a fair marksman, particularly if given a little time, and I am always willing to learn more. I listen for pro-tips, whether directed to me or just given in my presence, I observe as best I can how the more advanced shooters I see at matches prepare and when someone gives me specific advice, I am quite likely to try it and to research it and maybe modify it. One such piece of advice that made a huge difference in my control of the pistol was when someone spent some time to help me establish the grip commonly called Thumbs Forward. I have big beefy hands that were allowing me to shoot OK, even with a poor grip, but a solid grip instantly improved my shooting.

Old habits are hard to break, though, and the slightly unnatural support hand position was easy to forget to do until I was missing targets then I’d suddenly remember, correct the grip, and be instantly rewarded with better shots. Also, I was pretty bad about failing to reestablish that grip after a magazine change, or other action that transitioned my grip. I am largely over that and tend to grip consistently now, or at least more consistently. It now seems unnatural to hold the pistol wrong 🙂

That grip had been, until last Saturday, probably the single best improvement I had made in shooting skills. Now I have a few new skills to add to that list. They all tie together, too, and much of it starts with a good grip.

A good grip conducts the energy of recoil through your body and skeleton and ultimately into the ground, minimizing the movement of the pistol, giving better control and faster target acquisition. A solid stance will conduct that energy to the ground better. A poor stance will dissipate that energy into you and as noted by Newton, some part of you will move. Chances are, whatever it is will not help your shooting.

As IDPA is an action shooting sport, the shooter moves around through a course of fire to solve problems in a defensive scenario. Scoring is by time and every movement costs time. It takes pretty much a half second to take a step, whether at a shuffle, a walk or a run. A good stance lets you be positioned such that you are moving with all steps, in any direction. Otherwise, you might need to take a step to set up to move, then a step to move and 1 second is now gone from your time.

You will rarely enjoy the perfect stance, since you are subject to movement that may be restricted by obstacles, but you can make a good stance second nature. A good stance starts with your feet separated, laterally and medially. They should be about as far apart laterally as your shoulders are wide and medially, the toes of the rearward foot should be about even with the heel of the forward foot. Which foot is best to have forward varies with the situation. You should be bent at the knees and waist, with your shoulders over your knees, which both lowers your center of gravity and gives you better flexibility on directions you can move.

I learned what I knew about trigger control largely from old literature and years of practice. Get your sight picture, hold steady and slowly squeeze the trigger. Turns out, there is a better way.

The trigger has a bit of slack in it, where it takes a small amount of force to move the trigger until it reaches a point near release, where it becomes stiffer. If you are shooting something besides a Glock, the exact experience may be slightly different, but they pretty much all do this to some degree. Even the 1911 trigger has play to take up, though sometimes a gunsmith shortened that play with a trigger job. If this slack is taken out while the pistol is in transition to the next target, then you are ready to release the projectile sooner upon acquisition of the sight picture, saving precious time. Since you aren’t moving your trigger finger as much while the sight picture is in place, you have less opportunity to move the pistol as it fires. It’s a simple concept that made a surprisingly big difference in my shooting, but it’s maybe up there with the grip in it’s single cause improvement.

We covered some tips on dealing with barriers, like using your walkthrough to mentally mark where the edge of the barrier and the zero zone of the target line up so you can actually have much of your sight picture and slack out done before you emerge from the barrier and take a rapid shot, saving precious time. Similarly, if you need to move to advance around a barrier to address multiple targets in tactical priority, you want to set up the positions for your feet so that you don’t have to take any non-productive steps, saving precious time. In your walkthrough, you mentally mark where your rearward foot should land to set up any such steps ahead of time.

We covered target transitions. Until this class, I transitioned from target to target much like a tank, turning head and pistol together until the sight picture rests upon the target. A better way is to take advantage of the much higher speed at which you can move your head or eyes. As you finish one target, turn your vision to the spot on the next target to aim for, letting your comparatively slower body move to catch up and move the sights into your field of view on the target you have already acquired visually. While the pistol is moving, you can be taking out the slack in the trigger so that it’s ready to fire immediately when complete sight picture is acquired, all saving precious time.

We also covered moving, while maintaining grip, stance and trigger control. I had done some of this fairly successfully, but now armed with a better stance for moving and better trigger control, I was able to put 7 or 8 out of 10 shots onto a 6 inch steel plate at 10 yards while moving laterally. It was extremely gratifying and definitely made the day worth the price of admission!

Now I have specific drills to work on with my SIRT pistol as well as dry fire and range practice with my G20.

As an aside, I noticed today that my current classifier has expired as of March 15. I’m still Marksman in three divisions, but without a current classifier, I wont be able to shoot in any sanctioned matches. I have none scheduled before the next classifier shoot in mid-April, so that’s probably ok.