I have done a little bit of work on Sponge Bob, but more importantly, we racked up a few miles, just short of 4000 since the new speedo was put on way back in October of 2009. Much of this is ’round town miles, though a big chunk went on in a South Texas vacation/camping trip.

Sponge Bob has a new tire as of today. I pick it up on the way home in a few minutes. I also have a new headlight that I may even get on there tonight.

Last fall, Sponge Bob’s fuel pump quit. Without realizing it, it had actually been going for a while and was misdiagnosed as an ignition problem. When it died for good, at least it did it in town. Gabby trucked down the road to the nearest auto parts store for another unit, which was installed in pretty short order. He’s been reliable ever since. The mild but frustrating front end shimmy is expected to go with the old tire and while I have the wheel off for that, I will change the bolts that the speedometer sensor detects, which should stabilize the indicated speed. Change the headlight and I think Sponge Bob will be good for a while.

As for the Dragon trike, the two biggest things it needs are the shifter and the fenders, and arguably, the fenders could wait. The current shifter is such a pain to operate that it is difficult to properly tune the engine under and real driving conditions.

Replacing the shifter will involve welding on an alignment jig to bolt the new shifter to temporarily, cutting out all the old shifter parts, building a mount for the new shifter then removing the jig. The biggest question remaining is whether the shift lever can be easily removed from the new shifter to facilitate removing and installing the body.

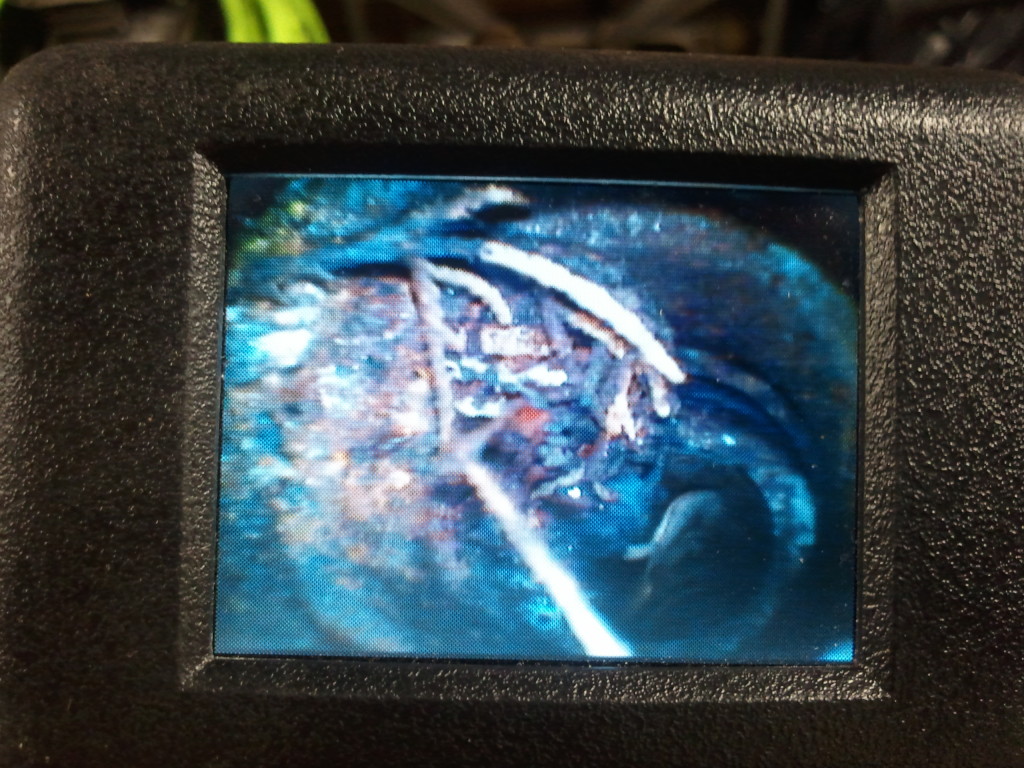

While I have the body off for the shifter work, I need to clean up some wiring issues. Some of the wires are too short and since they plug in to the back of the fuse blocks, tension has resulted in some wires coming unplugged. Similarly, the wiring harness on the body needs to be secured better. I used sticky taped wire looms, but most of them didn’t last as long as it took to finish assembling the trike. Those looms need to be epoxied to the underside of the body.